AI Industrial Imaging

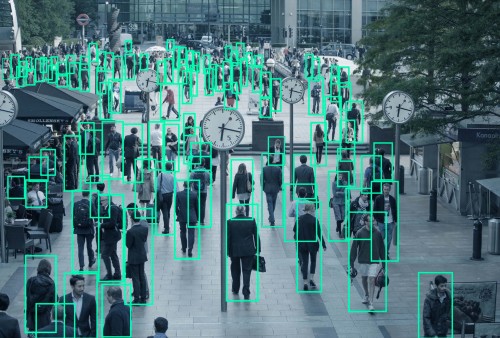

Takeleap's proprietary multi-algorithm platform offers an industrial imaging solution that allows computers to sort, inspect, monitor, process, analyze, and control a variety of processes in an industrial setting. The platform is prepared for integration into the recycling, mining, food processing, and pharmaceutical processing industries. Using inductive imaging and hyperspectral technologies, data is classified, enabling data acquisition to multiple levels of management, from decision-making to inspection and maintenance.

Inspection and Monitoring - Industrial image processing and data analysis offer the cutting-edge inspection technology required by management and quality control to extrapolate pertinent information from a production process.

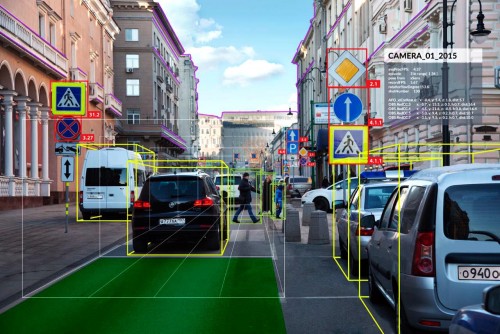

Smart Sorting – Takeleap’s imaging systems can accurately detect different materials according to their chemical composition. This analysis can help identify and separate products based on quality standards, color, shape, size, and chemical composition. It can even remove unwanted contaminants, which results in an improvement in the product’s quality.

Industrial Data Analytics - The control and analysis of materials during various manufacturing stages are necessary for complex production processes. Industrial data analysis enables precise control and forecasting of resource yield and maintenance cycles in the facility by inter-correlating the enormous amount of data from various systems in the line.

Takeleap partners with you to build state-of-the-art process analysis and control systems using our sensor system, industrial data analysis, and machine learning tools.

Call

Call

Mail

Mail