Computer Vision for Assembly Line Inspection

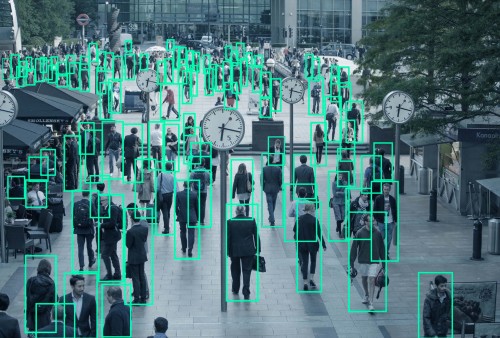

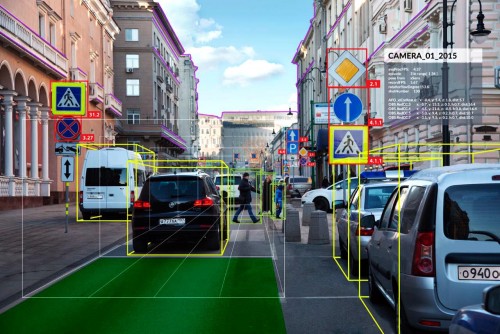

Manufacturing plants must ensure that their products and components from their production line comply with their strict quality, safety and production guidelines. By installing cameras at the right spots, we will be able to ensure that their product and component assembly standards are always met. This could include caps, labels, print, cracks etc.

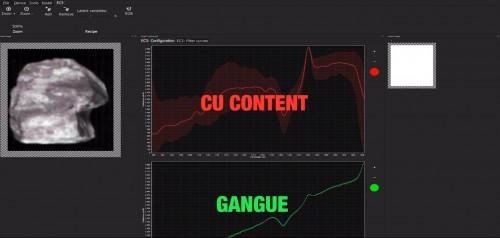

Computer Vision is used to check for broken or partially formed parts. As the products make their way through the production line, pictures are taken and transferred to a dedicated PC that processes the images, which then analyses further to check if the parts are the right colour, length, width, and whole.

By automating the whole process, we can also integrate a counting function. If a part is deemed defective, this information is logged, which then sends a signal to the counting functioning. When the parts reach the end of the production line, these anomalies are rejected, thereby removing the possibility of shipping defective products.

Call

Call

Mail

Mail